Top 20 Interview Question and answer in PLC

1.

What is PLC

A Programmable Logic

Controller (PLC) is an Industrial Computer that accepts inputs from switches

and sensors, evaluates these in accordance with a stored program and generates

outputs to control machine and process

(Or)

It is a specialized

computer used to control machines or process. It uses programmable memory to

store instructions and execute special functions that include on/off control,

timing, counting, sequencing, arithmetic and data handling.

It is microprocessor based device.

2.

What is Difference Between PLC and Micro-Controller

|

|

PLC |

Micro-Controller |

|

1. |

It is a

special computing device designed for use in industrial control systems and other

systems where the reliability of the system is high. |

It is a

small, single-chip computing device containing one or more processing cores,

with memory devices embedded alongside programmable dedicated and general

purpose input and output (I / O) ports. |

|

2. |

PLCs can

generally be called a high level microcontroller. |

It is generally

can be referred to as a low-level microcontroller. |

|

3. |

The processor

module consists of the central processing unit (CPU) and memory. In addition

to a microprocessor, the CPU also contains at least one interface with which

it can be programmed (USB, Ethernet or RS232) together with communication

networks. |

The microcontroller implements everything on a

single chip, from the CPU to the I / O

ports and interfaces required for communication with the outside world. |

|

4. |

The power supply

is usually a separate module and the I / O modules are separate from the

processor |

There is no

separate module in this power supply. It is built with processor |

|

5. |

PLCs are

designed to communicate with industrial grade sensors, actuators and communication

modules and thus get current and voltage ratings that are often incompatible

with microcontrollers without additional hardware. |

Microcontrollers have sensors, actuators and

modules designed to meet their specific needs, which may be difficult to

connect to a PLC. |

|

6. |

PLC is

designed for use in industrial setups and thus has been reinforced to

withstand various adverse conditions associated with that environment, such

as extreme temperature ranges, electrical noise, rough handling and high vibration |

Microcontrollers are not designed to serve as

stand-alone devices such as PLCs. They are designed to be embedded in a

system. This explains their less rugged appearance compared to PLCs. |

|

7. |

The PLC is

designed for use by both highly trained automation experts and factory

technicians with little or no formal training |

Microcontroller designers must have a good

understanding of electrical engineering principles and programming to design

complementary circuits for the microcontroller. |

|

8. |

PLCs were

originally designed to be programmed using a programming image that mimics

the connections / schematics of logic relay diagrams. This reduced the

training requirements for existing technicians. |

It usually requires a high level of experience in

the programming language used and a general understanding of the principles

of firmware development. Programmers usually need to understand concepts such

as data structures and a deep understanding of the microcontroller

architecture is required to develop a very good firmware for the project. |

|

|

PLCs are the main control elements used in industrial

control systems. They are used in the control of industrial machines,

conveyor belts, robots and other machines in the production line. They are

also used in SCADA-based systems and in systems that require a high degree of

reliability and can withstand extreme conditions. |

Microcontrollers are being used, they are now being adapted for

certain applications for which microcontrollers were considered unsuitable,

from mini-do-it-yourself computers to various complex operating systems. |

3.

What are the data types used in Counter

A

counter is a simple device aimed at one simple thing - counting.

There are up-counters (they only count 1,2,3

...). These are called CTU, (count up) CNT C or CTR. These counters are below

(they only count 9,8,7, ...). These are usually called CTD (count down), when

they are a separate instruction.

These are also up-down counters (they count 1,2,3,4,3,2,3,4,5, and down or down.) ..) These are usually UDC (up-down counters) It is said, when they give different instructions.

Typically

counters can count from 0 to 9999, -32,768 to +32,767 or 0 to 65535. Why the

weird numbers? Because most plc's have 16-bit counters. We'll get into what

this means in a later chapter but for now suffice it to say that 0-9999 is

16-bit BCD (binary coded decimal) and that -32,768 to 32767 and 0 to 65535 is

16-bit binary.

4.

What is the Difference between Relay Logic circuit and

PLC circuit

|

S.NO. |

Relay Logic |

PLC Logic |

|

1. |

Relay logic is a hard wired control system

using instrumentation, switches, timers, relays, contactors, motors and

actuators. Traditional machine and process automation was accomplished using

relay logic. |

Relay logic in

a PLC is the method of formulating logic expressions to automate machines and

processes in industrial applications. The programming language used to create

relay logic in a PLC is called Ladder Logic. |

|

2. |

Requires a lot of switchboard space. |

Easier to

develop complex logic expressions with ladder logic software. |

|

3. |

Less

reliability compared to plc logic |

Increased

reliability with PLC life easily reaching + 10years, |

|

4. |

Solving

problems is extremely difficult. |

Solving

problems is very easy. |

|

5. |

Changes to

control functionality are complicated and seriously annoying. |

Virtually

maintenance-free compared to relays. |

5.

What is the role of PLC in automation?

In automation, PLC plays an important role in controlling and monitoring industrial applications. It has both hardware and software.

This controller can be run or operated automatically and manually. For its operation it requires extra manpower, time, utility and precise operation in the system. It is useful to increase the reliability and stability of the system. It performs precise edits in a very short time. This is one of the reasons why PLC is widely used in industry today.

6. What are the different components of PLC?

PLC

has several components. Each part is linked to specific PLC operations and

functions.

These

modules provide input to the PLC and output. Input and output can be both

digital and analog.

This

part is responsible for providing AC or DC power to operate the PLC.

Several devices can be connected to the PLC. Communication protocols are used to exchange information from one device to another.

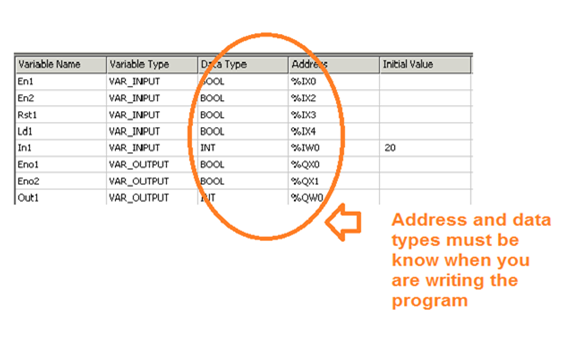

You

must write a programming language to implement PLC logic.

These

are the six basic components of the PLC.

ABB PLC

AB (Rockwell) PLC

Siemens

Delta PLC

Mitsubishi PLC

Honeywell PLC

Omron PLC

Schneider PLC

Hitachi PLC

Fatek PLC

Bosch PLC

GE (General Electric) PLC

educational

purposes and also in largest industries.

8. What is LD in PLC?

The modular PLC consists

of the number of input or output modules, the controller processor and the

communication controller. This hardware composition of these modules is called

"rack or chassis".

10.

What is the

PLC scan cycle?

When the PLC program is

running, multiple repetitive processes take place. This is the whole process

called a PLC scan cycle.

This scanning program

consists of reading input data, running the programming logic and updating the

output data in one cycle.

The scan time is a time

required for continuous scanning of programs. It will take about 10ms-15ms

times.

11.

What is the MCR?

MCR is the short abbreviation of “Master

Control Relay”. It is a type of instruction used in Siemens PLC software. This

instruction is used to shut down the process.

MCRD (Master Control Relay

Deactivate),

MCR <(Master Control

Relay Less),

MCR> (Master Control

Relay Greater).

12.

What is a communication protocol?

The system communicates

with the two or more communicating devices to transfer digital data or

information. This communication is subject to a number of rules called

"Communication Protocol".

The standard definition communication

protocol is a set of rules that govern data communication.

13.

What different types of communication protocols are used in PLC?

|

1 |

EtherNet / IP |

|

2 |

Profibus |

|

3 |

Modbus |

|

4 |

Interbus |

|

5 |

ProfiNet |

|

6 |

ControlNet |

|

7 |

DeviceNet |

|

8 |

DirectNet |

|

9 |

CompoNet |

|

10 |

RAPInet |

|

11 |

EtherCAT |

|

12 |

MelsecNet |

|

13 |

Optomux |

|

14 |

DF-1 protocol |

|

15 |

HostLink protocol |

|

16 |

MECHATROLINK |

|

17 |

DH- Data highway |

|

18 |

PPI - Point to point |

|

19 |

EtherNet Powerlink |

|

20 |

MPI- Multi-Point Interface |

|

21 |

EGD- Ethernet global data |

|

22 |

AS-i- Actuator Sensor interface |

|

23 |

OSGP- Open Smart Grid protocol |

|

24 |

DNP3 - Distributed network protocol |

|

25 |

SDS - Smart Distributed System Protocol |

|

26 |

PieP- Process Image Exchange Protocol |

|

27 |

SRTP- Service Request Transport Protocol |

|

28 |

BSAP-Bristol Standard Asynchronous Protocol |

|

29 |

FINS- Factory Interface Network Service Protocol |

|

30 |

HART Protocol for addressable external transducer |

Recommended standard

protocol (RS-232, RS-422 and RS-485)

These are the main

communication protocols used for the PLC and other network connections. These

protocols are supported by various PLC software brands. The communication

protocols depend on three fundamental parts, such as baud rate, network length

and the number of modes.

14.

What types of

sensors are used in automation?

The sensor is an electronic device that detects various parameters from the physical environment and passes them as input to the PLC controller.

The sensor can be either digital or analog depending on the type of signal it is passing through.

Here are different types

of sensors used to communicate the different parameters to the controller.

|

1. |

Inductive proximity sensors |

|

2. |

Capacitive proximity sensors |

|

3. |

Optical sensors |

|

4. |

Ultrasonic sensors |

|

5. |

RTD sensors (Resistance Temperature Detectors) |

.

These two terms refer to the data transfer between PLC and connected PC.

Upload means data transfer from PLC to PC.

Download means data

transfer from PC to PLC.

The functions of the PLC are,

2. Monitoring of the system and the plant

3. Control the position or movement of the system

4. Detection of the fault condition in the system

18. What are the different types of counters used in PLC?

The PLC counter is divided into three different types.

1. Up Counter

2. Down counter

3. Counter up / down

The up / down counter is usually used in PLC programming.

19.

What

are the types of PLC?

2. Modular PLC

Compact PLC: In Compact PLC the I / O capacity is defined and determined by the manufacturer. They are used for small-scale applications.

Comments

Post a Comment

If you have any Doubts plz let me know